Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The processing process of Aluminum Plates

1. Casting: The first step in the processing of aluminum plates is casting. Aluminum ingots are melted in a furnace and then poured into molds to form the desired shape of the plate.

2. Rolling: After casting, the aluminum plates are rolled to achieve the desired thickness. The plates are passed through a series of rollers that compress and stretch the aluminum to the desired thickness.

3. Annealing: Annealing is a heat treatment process that helps to soften the aluminum and improve its ductility. The aluminum plates are heated to a specific temperature and then slowly cooled to relieve internal stresses and improve the overall quality of the material.

4. Cutting: Once the aluminum plates have been rolled and annealed, they are cut to the desired size and shape using cutting tools such as shears or saws.

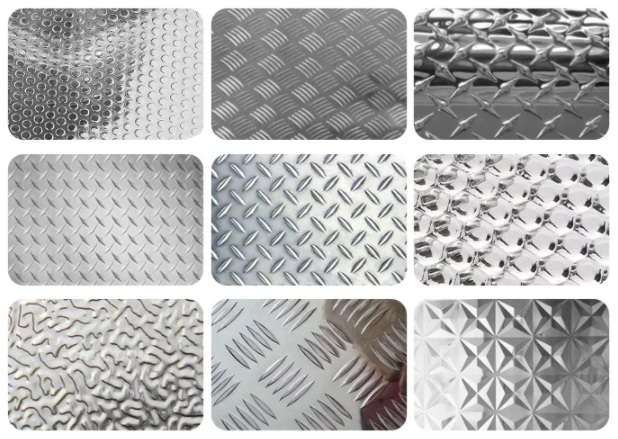

5. Surface treatment: Depending on the application, the aluminum plates may undergo surface treatments such as polishing, anodizing, or coating to improve their appearance and corrosion resistance.

6. Quality control: Finally, the processed aluminum plates undergo rigorous quality control checks to ensure they meet the required specifications and standards before being shipped to customers.

Overall, the processing process of aluminum plates involves casting, rolling, annealing, cutting, surface treatment, and quality control to produce high-quality aluminum plates for various industrial applications.

Advantages of exporting aluminum plates to China

1. Large market: China is the world's largest consumer of Aluminum Products, making it an attractive market for exporters of aluminum plates.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.