Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

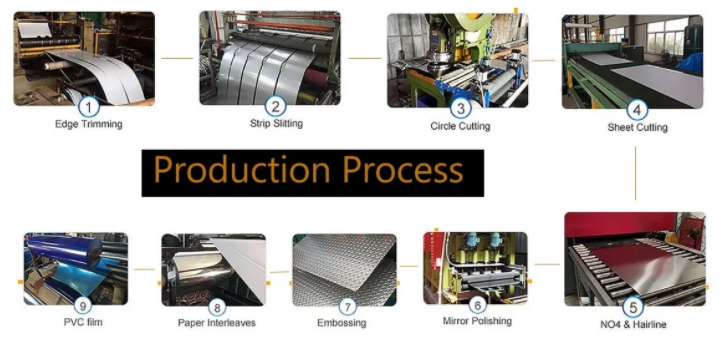

The production process of aluminum tubes

1. Raw materials: The main raw material used in the production of aluminum tubes is aluminum ingots. These ingots are melted down in a furnace to create molten aluminum.

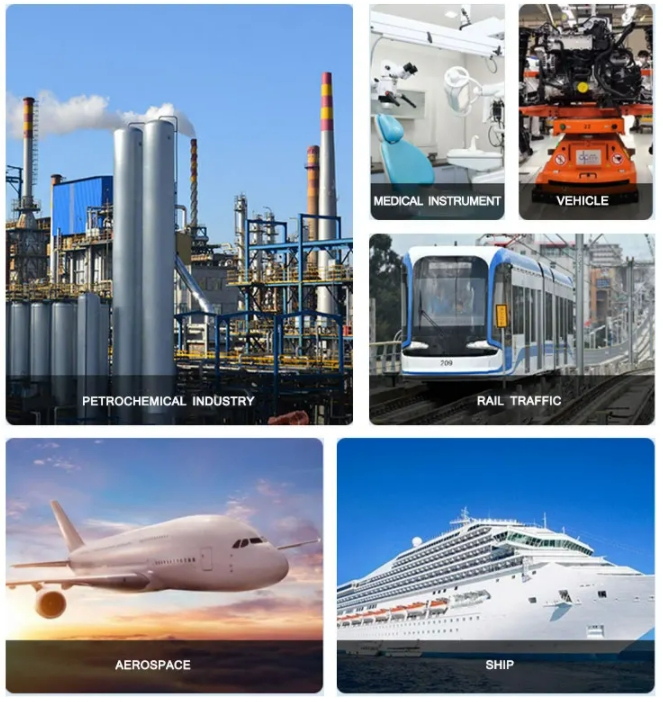

Aluminum tubes can be applied in various industries and for different purposes, including:

1. Aerospace and aviation: Aluminum tubes are commonly used in aircraft structures, fuel lines, hydraulic systems, and heat exchangers due to their lightweight and corrosion-resistant properties.

2. Automotive industry: Aluminum tubes are used in the manufacturing of radiators, air conditioning systems, exhaust systems, and other components in vehicles to reduce weight and improve fuel efficiency.

3. Construction: Aluminum tubes are used in the construction industry for scaffolding, handrails, curtain walls, and structural components due to their strength, durability, and resistance to corrosion.

4. Electrical and electronics: Aluminum tubes are used in the production of electrical conduits, heat sinks, and other components in electronic devices due to their thermal conductivity and electrical resistance properties.

5. Medical industry: Aluminum tubes are used in the manufacturing of medical devices such as catheters, IV poles, and surgical instruments due to their biocompatibility and sterilizability.

6. Packaging: Aluminum tubes are used for packaging products such as toothpaste, ointments, and pharmaceuticals due to their lightweight, barrier properties, and recyclability.

7. Furniture: Aluminum tubes are used in the manufacturing of furniture such as tables, chairs, and shelving units due to their lightweight, durability, and modern aesthetic appeal.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.